A woman-founded tech startup has created a plastic alternative from methane. The California-based company, called Mango Materials, is now at the helm of a sustainable revolution in the biotech industry.

Engineers Allison Pieja, PhD, and Molly Morse, PhD, and environmental microbiologist Anne Schauer-Gimenez, PhD, are the masterminds behind the startup, which received its first round of funding back in 2012.

Mango Materials uses methane from biogas waste to make the plastic alternative. Through a process called methane fermentation, the company transforms the methane into a biodegradable biopolymer called polyhydroxyalkanoate, or PHA.

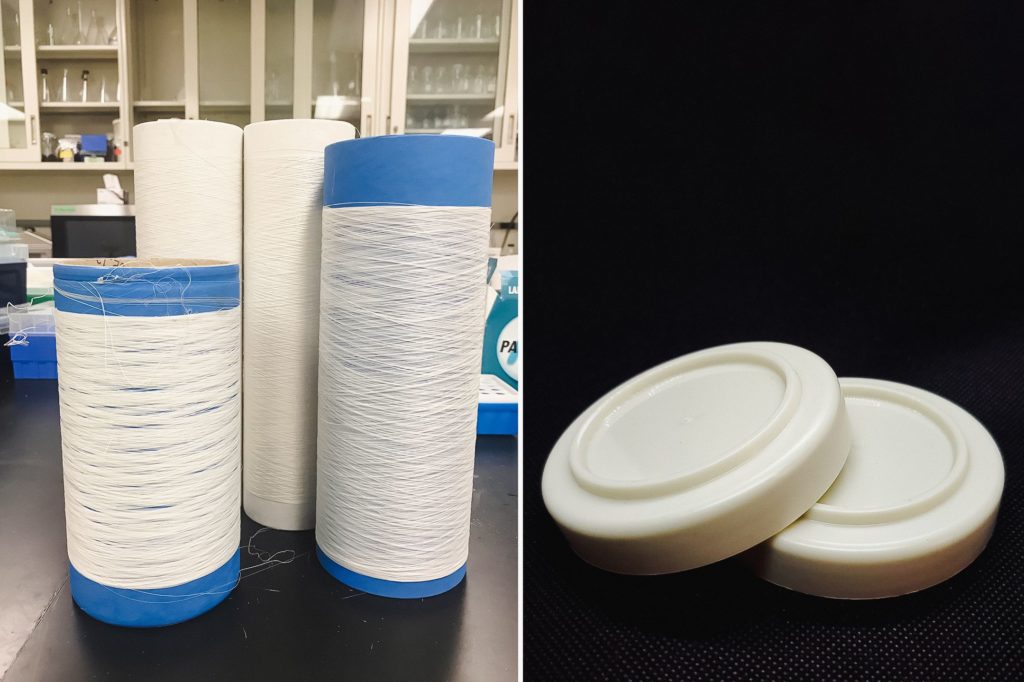

Plastic pellets are used to make the vast majority of plastic products. However, the startup’s sustainable PHA pellets, called YOPP and YOPP+, are an eco-friendly alternative because they are fully biodegradable and compostable.

Similar to conventional plastic pellets, they can be used in plastics supply chains. In an email, Morse tells LIVEKINDLY the company is focused on using its plastic alternative in fibers, such as clothing and shoes, and injection molding applications. These include jars, bottles, and bags.

Polyhydroxyalkanoate, aka PHA, is a biopolymer made from methane gas. | Mango Materials

Methane As a Plastic Alternative

In addition to fighting plastic waste, the PHA pellets are helping to mitigate climate change.

According to NASA, methane is a potent greenhouse gas that traps heat 28 times more effectively than carbon dioxide. NASA notes that concentrations of the gas have surged by more than 150 percent “since industrial activities and intensive agriculture began.”

In the 20th century, the administration adds that methane was the cause of approximately 23 percent of climate change.

Mango Materials helps to reduce these emissions by partnering with wastewater treatment plants, landfills, and agricultural facilities to take on their methane waste. Through the fermentation process, the company then feeds the methane gas to bacteria. The bacteria are able to produce pure P3HB—a type of PHA—naturally. The P3HB is then used as a base polymer for the company’s YOPP and YOPP+.

Morse says companies are already using the sustainable plastic alternative in their value chain. And even if the materials wind up in landfills, she says they won’t harm the planet.

“If YOPP/YOPP+ is accidentally discarded in the environment, it can be biodegraded by many naturally occurring microorganisms,” she explains. “We never want materials to end up there, but if they do they will not contribute to persistent plastic pollution.”